When most people think of NASA or Aerospace Systems, they don’t think “additive manufacturing”.

When most people think of Materials Science, they don’t think “power generation”.

When most people think of Tech Sprints, they don’t think “new partnerships”.

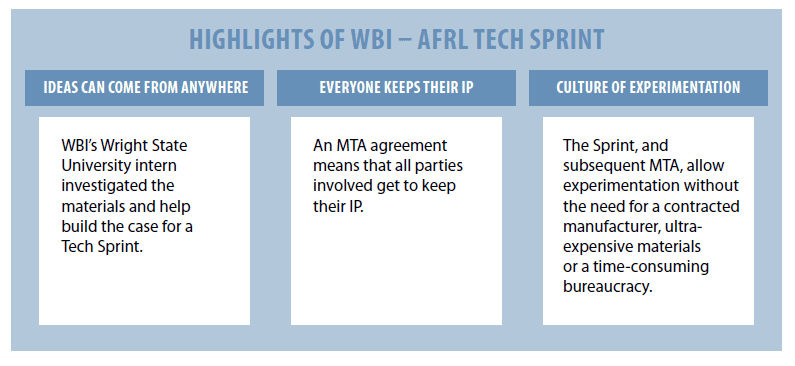

Successful Tech Sprints are usually defined by producing prototypes, designing a product or coding a solution. When the Air Force Research Laboratory’s Aerospace Systems Directorate (AFRL/RQ) and Wright Brothers Institute completed the "Additive Manufacturing for Power Generation" FY18 AFRL Incentives for Innovation Tech Sprint, they expanded the definitions of success. Joe Althaus, Rapid Innovation Program Manager at Wright Brothers Institute likes to call Tech Sprints, “Direction with momentum.” That momentum can accelerate research with partnerships being the successful solution of a Tech Sprint.

New Partnerships

The 2018 Tech Sprint resulted in a Material Transfer Agreement (MTA) between two directorates within AFRL and UTC for the study of additive manufacturing of soft magnetics for the purpose of power generation. The MTA allows AFRL and UTC to collaborate using newly developed technology (OpenSLM additive developed with NASA SBIR funding) and novel materials concepts. The agreement accelerates research because it pushes the boundaries of power generation and additive by blending the two. AFRL is leveraging other government investments (NASA SBIR) to accelerate the research by leveraging an existing experimental metal powders printer, alongside additive experts, rather than developing their own system. AFRL/RQ and RX will focus on optimization of the material, manufacturing, and operational parameters required for power generation applications. The agreement with UTC will allow use of state-of-the-art additive technology to demonstrate tractability for the area of research.

WBI will stay involved from a facilitation perspective.