Wright Brothers Institute Leads, Connects Department of Defense Effort to Rapidly Produce Low-Cost Ventilators

15.04.20 10:20 PM By Jennie Hempstead

By: Laura Dempsey

Dayton, April 15, 2020: As coronavirus disease (COVID-19) spread throughout the world, it quickly became clear that the U.S. health care system would be unable to meet the projected demand for ventilators, resulting in a shortage that would surely cost lives.

Defining the Challenge, Exploring Solutions

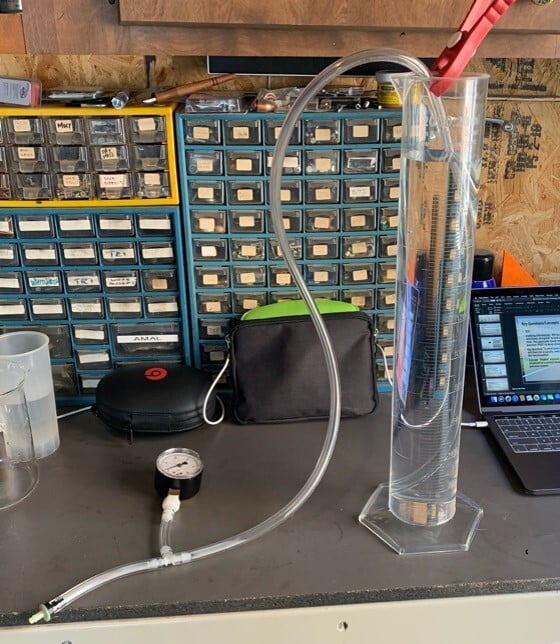

On March 23, 2020, the Sprint participants gathered via Zoom, the online meeting utility, and began defining the issue and brainstorming solutions. Courses of action included scaling up existing manufacturing; modifying medical equipment such as C-PAP machines and bag ventilators such as those used by first responders; modifying commercial off-the-shelf equipment such as scuba gear; designing a do-it-yourself 3D printed version; and some sort of “Apollo 13” approach, cobbling together available, existing materials. The team was able to pin down requirements for approval from the Federal Drug Administration (FDA) and looked at whether it was necessary to get that approval given the urgent nature of the crisis. (It is, but emergency waivers of some requirements are on the table.) The Sprint concluded with several white papers distributed to various military networks.

These white papers will provide additional testing, prototyping and supply chain insights for other Department of Defense efforts, including the recent Defense Health Agency (DHA) “Hack-A-Vent” Challenge.

Subscribe to our newsletter

Stay informed about our latest updates through email. Subscribe here.