“Essentially,” said Althaus, “if you’re not found in the first five minutes, there is a potential you’re going to be out there for a while.”

The survival kits in use today are essentially the same as those put in place during the 1970s F-16 modernization. Over the past 40-plus years, technology advances and changes in the theater of war have led to a need to modernize the survival equipment the pilot has access to.

In addition, Althaus pointed out that in a 5th generation aircraft, a pilot may find themselves taking off from a U.S. location, flying over the Arctic Circle, and landing in a desert. “Any particular mission could take you over many different operating environments, with the chance of going down in any one of them,” he said.

This ongoing issue was the basis for a challenge presented to WBI’s Rapid Innovation team of Althaus, Tom Mitchell and Matt Sunday. The call came from Dr. Deirdre Mahle, the Air Force Research Laboratory’s (AFRL) Plans and Programs Special Operations Engagement Lead. She was reacting to an AFRL push for innovative solutions that ensure basic hydration, nutrition and personal safety elements are in place for isolated personnel.

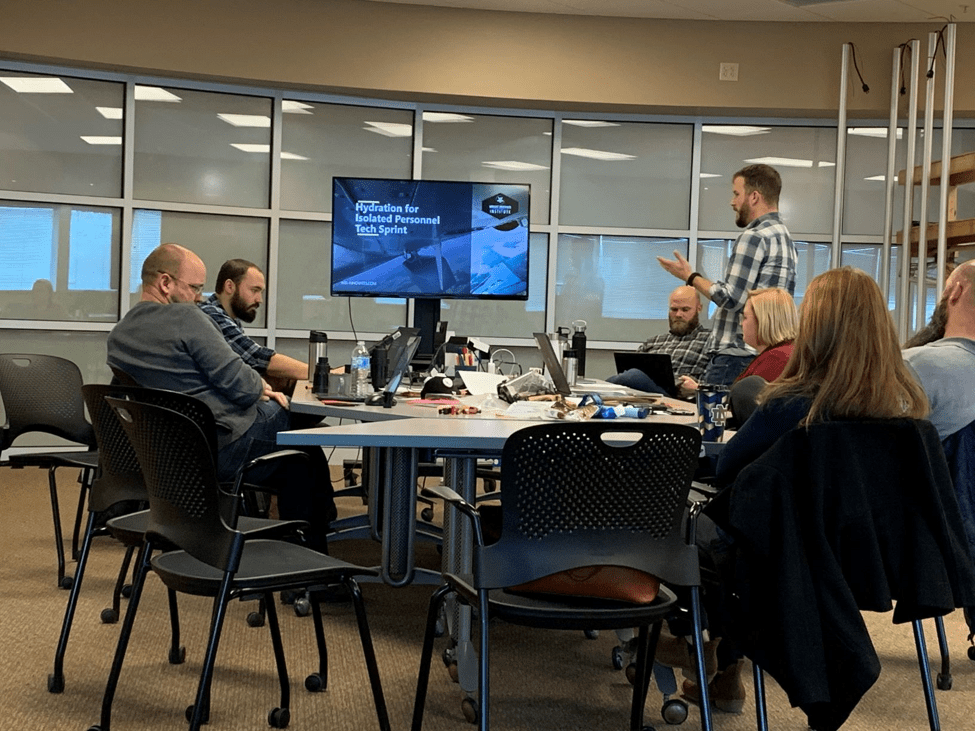

The parties agreed on one of WBI’s tried and true practices: a technology Sprint. Sprints are intensive, weeklong efforts that focus on deconstructing a broad problem to find its most essential and impactful components. The combination of facilitation and an aggressive agenda enables concentration away from daily interference and distractions, allowing the team to rapidly determine a path forward.

In Althaus’ words, “the point of a Sprint is to focus on a problem – get like-minded teammates focused on what we’re trying to solve. We bring something to life and have folks tear it down, point out what will and won’t work.”

“A lot of the Sprint is momentum,” he continued. “You stay together and stay focused on the problem. The minute people get up, they’re on their phones, things come up, they wander off …..”

“The real key to everything is the divergent thought,” added Mitchell. When problem sets are shared with experts of other specialties, insights can be leveraged to uncover new solutions.

They pulled together a team of 12 people from AFRL, Air Combat Command, and an Air Force SERE (Survival, Evasion, Resistance and Escape) specialist. Once assembled, they decided to focus on hydration, attacking it on three fronts: Capturing water from the environment; physiology, or ways the human body can use water more optimally; and recycling liquid the body is constantly excreting.

Their task was to provide enough water to last 28 days, using cross-cutting technologies and an innovative, collaborative approach. The stated objective was to identify a hydration source that would reduce weight and volume by 25 percent or more compared to what is currently in the survival seat kit.

They created the concept of a “water budget” – meaning the team focused on how to best balance approaches to meet the total water required with the realization that each environment will be different and there is likely no “silver bullet.” The team brainstormed ways to capture and recycle urine, sweat, and breath. After moving through some creative iterations, they settled on a mask that collected and filtered vapor from breath.

In true innovative Sprint fashion, Sunday headed to Home Depot and serendipitously found a clearance bin full of sprinkler parts. Back at WBI, Mitchell’s 3D printing expertise led to creation of the only piece not bought off the shelf – the collection vessel.

“This filter didn’t exist in the morning, and by 3 p.m. it did,” Althaus said. “We have that unique capability – to come up with anything and hold it in our hands the same afternoon.”

Senior Master Sergeant Michael Slaton, ACC SERE Program Manager, enjoyed the Sprint method. “I love the ideas, excitement, and general passion for solving problems. If we do not get there with this Sprint, maybe we take one small win and expound upon it,” he said.

Brittany Fouts of the 711th Human Performance Wing and one of the Sprint’s government leads,” was more than pleased. “I was happy we were able to identify actionable results from the Sprint. Going in, I was anticipating a final report of potential courses of action as the primary deliverable, so development of a proof-of-concept breath capture device and identifying multiple commercial off-the-shelf solutions exceeded my expectations,” she said.

The team produced a good result, even after having put the nutrition and thermal issues aside.

“If we’d done all the topics, it would have diluted the results here,” said Sunday.

The Sprint team is poised to continue the work on capturing water from the environment and recycling water from the body to hit those initial requirements and to fulfill the “water budget” concept. The team plans to stay engaged with the Program Office and keep the needs of the user in mind with continual interaction to drive the ultimate solutions toward transition.